Carburetor Update

December 8, 2024

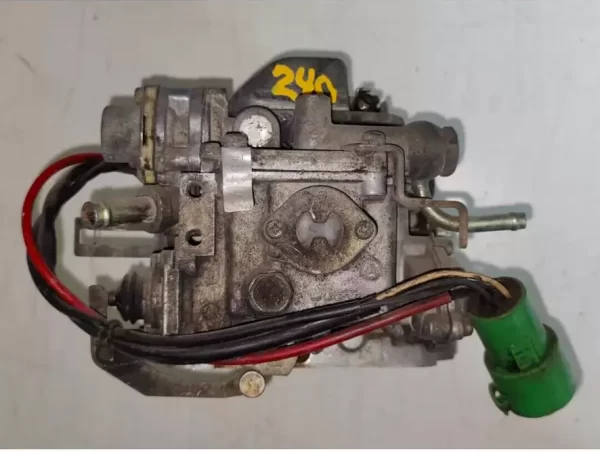

Jim at TLC performance finished the carburetor restoration in November but the USPS lost it during the return shipping. That was sad news for sure. Jim is now working on one he found on ebay.

Jim informed me that…

“It is a 1983 Federal carb, so has a couple of slight differences compared to the missing carb, none of which are deal breakers.

- It doesn’t have a A/C idle up actuator that raises RPM when AC kicks on at idle. Temporary solution: turn up idle speed slightly so AC doesn’t lug the engine down at idle.

- Doesn’t have a small vacuum pipe that connects a port on side of carb to vac hose in front. Solution: extend vacuum hose to reach port on carb, bypassing 4″ pipe.

- Has extra (unnecessary) throttle return spring gizmo. Solution: remove return spring assembly.

- Has 4 extra emissions vacuum fittings. Solution: cap off unneeded fittings.”